Case Study

Client: WHP

Scope

The procurement, fabrication and installation of the following:

Description

-Supply and installation of 6No- antenna poles fabricated from 114.3 x 6.3 mm wall complete with 10 mm connection

-Supply and installation of 2No- Tripod Dish poles complete with diagonal bracings.

-Supply and installation of 1No- Roof- pod grillage steelwork for sector C complete with 25 x 5, 41/100 pattern flooring panels and 42 mm handrails standards and 42 mm rails, 150 x 6 flat kick along with access ladder as self-closing gate

-Supply and install 1No-Roof- pod grillage steelwork for sector A & B complete with 25 x 5, 41/100 pattern flooring panels and mm handrails standards and 42 mm rails, 150 x 6 flat kick plates along with access ladder as self-closing gate

-Supply and install 1No-cabinet roof grillage steelwork complete with 25 x 5, 41/100 pattern flooring panels and mm handrails standards and 42 mm rails, 150 x 6 flat kick plates

-Works based on CE Class 2

-Supply and installation of 12No- RRU/BOB poles for each sector secured main PFC sections as per drawing 511

-Supply and installation of 4No- RRU/BOB poles for each sector secured main PFC sections as per drawing 508

Plinths & Cable Tray

The procurement and construction of the following:

-Existing plinths to be broken out and covered with green/grey mineral felt to waterproof

-Construction of 10No- plinths 350 x 350 x 380 high for Sector A

-Construction of 2No- Steel stool plinths 150 x 150 x 10 box section Sector C

-1No- plinth 350 x 600 x 250 high for Ladder feet

-We allowed 2No- layers of underlay mineral felt followed by 1No- green/grey 3mm top mineral felt

-Main plinth design based on WHP drawings issued with tender

-All plinths covered with code 4 lead caps, 8No- lead caps will be special caps due to the location of the plinths.

-Unclip existing feeders and rope back or lay on floor ready for new cable tray installation

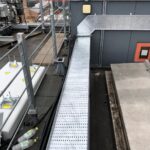

-Supply and installation of 600 mm wide cable tray x 24-metres to support feeders complete with 2No- bends supported on rubber blocks and heavy-duty stand-off brackets

-Supply and installation of 450 mm wide cable tray x 66-metres to support feeders complete with 5No- bends and 1No- Tee uneven Tee and heavy-duty stand-off

-Installation of new Unistrut and securing of new tray supports fixed to existing structure

Get in touch

Head Office

-

Structural Fabrications Limited

2 Castings Road

Sir Francis Ley Industrial Park South

Derby

DE23 8YL

Site Links

Services

Contact Info

t: 01332 747400

f: 01332 747447